Our speciality : The Vibratory Bowl Feeder

What’s a bowl feeder ?

A bowl feeder is useful to feed automatically industrial parts. The goal is to provide to the production line, assembly machine or robot, oriented parts.

A bowl feeder is used in several industrial sectors like : cosmetic, car industry, pharmaceutical, agribusiness, mechanical…

If you want to know more about, you can visit our page learn with us

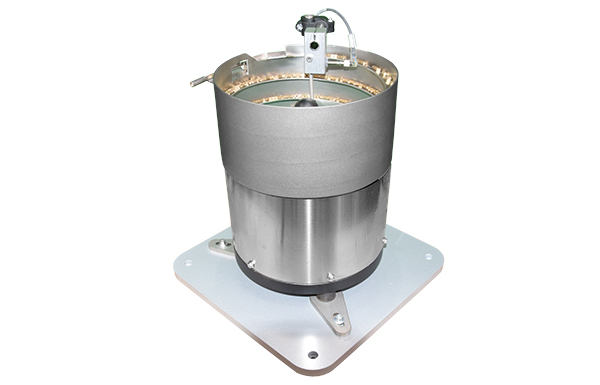

The full bowl feeder system : the reliability and convenience alliance

A vibratory bowl feeder is composed by 4 essential items :

- One vibratory hopper or lifting belt hopper (Autonomy unit)

- One bowl feeder (positioning/orientation unit)

- One vibratory linear feeder track or conveyor belt (Feeding unit ).

- One base plate on which the 3 previous items are mounted.

We can add to these 4 items :

- One frame which support the base plate.

- One sound enclosures to reduce the noise and respect the standards

- One separation or handling unit to enable a unitary feed.

- One electrical cabinet to manage the automatism.

- Industrial vision camera associated to the vibration feeding system.

- Others special demands depending of the customers’ needs.

Our vibratory bowl feeders are personalised according to the specifical needs of our customers. It’s the reason why, it’s essential for us to be a local actor able to understand your projects and so to offer you the best solution.

Our CAD department is the heart of your project management. It offers you innovative solution and turnkey project.

Bowl Feeder specifications

We have an extensive range of bowl feeder which make possible to feed a wide variety of parts.

The smallest of our bowl top measures 160 mm diameter and the biggest measures 1300 mm diameter.

To create vibration, we have to add a vibratory base under the bowl top. This one vibrate thanks to the electro-magnet, the coil and leaf springs. The vibratory base can work at 50 Hz or 100 Hz depending on the technical possibilities for the parts orientation.

We call the bowl top and the vibratory base a bowl feeder.

Upstream to the bowl feeder, we often place an hopper. It can be a vibrating hopper (Trough on a linear vibratory base) or a lifting belt hopper (belt driven by an electrical motor). The main difference between these two items is the loading height.

Downstream, to the bowl feeder, we often place a linear feeder (track mounted on a vibratory linear feeder) or a conveyor belt. The choice between these two items is made depending to the parts feeding posibility at the output.

Finaly, downstream to the linear feeder, we can place a separation or an handling system which can do several movement depending to the customer needs.

The bowl top technology

ingsThe bowl feeders PULSA are equipped with stainless steel bowl tops (304L or 316L). We have 3 kinds of technologies : cilyndrial, conical, or stepped bowl.

It’s possible to do several types of finishing :

– Mirror polished

– Sandblasting

– Shot-peening

– Habasit coating

– Polyurethane coating

– Teflon coating

Based on the parts to feed, the required cycle time and the constraints linked to your sector, we can apply these finishings, and more for special applications.

Conical bowl top

Cylindrical bowl top

Stepped bowl top

Parts feeding for robots with bowl feeder

Robotic is each time more involved in the industry. The bowl feeder is also used to feed, orientate and place parts one by one for a robot. In this case, we design and manufacture adapted systems for the robot environment.

We add at the bowl feeder output one separation or handling system useful to provide oriented parts one by one to the robot.

Our feeding systems can be personalized taking into account your constraints (design of your gripper, position of the jaws, the kind of hangling (clamp, vacuum, fitting), robot stroke, cycle time …). Depending on these datas, we adapt our technical offers to give you the best solution.

Common questions around the bowl feeder

Which informations are necessary for an enquiry ?

– The production rate to reach

– The required part position at the output

– The number of parts type to feed

– The available space for implantation

– The output height

– The loading height at the input

– The required autonomy (time or parts quantity)

– The industrial sector in which the system will work

Can we retrofit existing systems ?

Yes of course, we can even go further. If your existing system is compatible with a new workpiece you want to feed, we have the capacity to modify it. Like that, you will be able to produce using your old system.

How is a bowl feeder manufactured ?

It’s an on-demand and customed made manufacture. For this reason, its shape (conical, cylindrical or stepped), its size (160 mm to 1300 mm) its coating will depend of the required production rate and the tooled difficulties.

Once these variables defined, our technicians tool the bowl top and machine the output with the aim to orientate the parts and reach the production rate.

How the first level maintenance is done ?

It is simple considering the high reliability of the components.

You have to check the air gap distance, the leaf springs quality, the coil quality and bowl top fixation.

For a more complex maintenance, you should contact a bowl feeders specialist.

Some examples of bowl feeders in video

Bowl Feeder for car industry. Feeding system for springs. Feed rate : 30 parts per minute

Explanatory video about the principle of operation of a bowl feeder.

Our news

Welding know-how for bowl feeder manufacture

Welding know-how for bowl feeder manufacturingIn the Bowl Feeder manufacturing process, welding is...

France

186 rue des Charmilles

Parc d'activités du pays des couleurs

38510 ARANDON-PASSINS

France

www.pulsafrance.com

Copyright © 2025 - TechFeeder trademark