Handling and Separation systems

One part of our job is to provide oriented workpieces to a defined area, with the goal for the customer to take easily the parts with his machine. We design and manufacture handling and separation systems located downstream of the feeding system. With these systems, we are able to provide workpiece one by one and isolated or separated with a specific center axis.

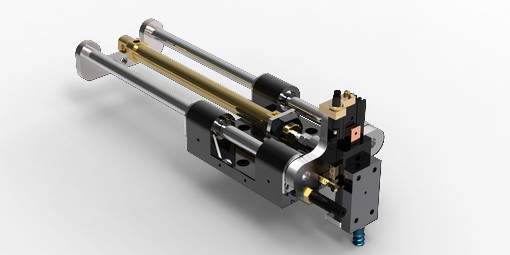

Linear handling system for drop off

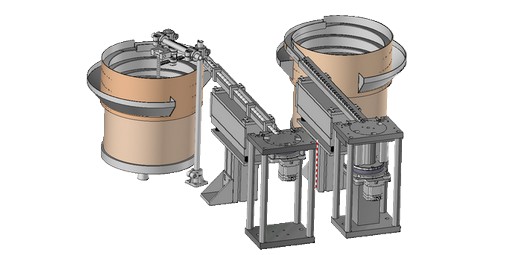

Bowl Feeders and multi-positions separators

Handling and separation specifications

We are expert in handling and separation systems. We offer solutions depending of your needs and budget. According to the most suitable workpieces assembly, the required cycle time and your specific constraints we will be able to give you the best answer.

Each handling system is designed for your projects as we personalized it to your needs.

We can offer:

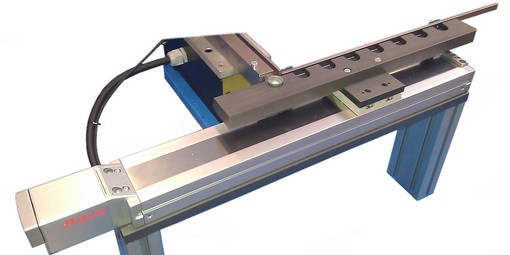

– One track separator to provide one by one the workpieces to the customer system. Usually, we make it with pneumatic axis.

– Multi-tracks separator to provide several parts spaced by a defined center axis. We make it with pneumatic or electrical axis, depending of the number of required tracks.

Handling and orientation

Sometimes, with the feeding system it is difficult to orientate the workpiece in the required position.

The answer to the customer needs is to design and manufacture handling systems with parts orientation.

To do it, and depending of the orientation complexity, we use :

- Inductive sensors

- Optic sensors

- Laser sensors

- Vision sensors

- Pneumatic or Electrical axis

8 tracks separators mounted on an electrical axis

France

186 rue des Charmilles

Parc d'activités du pays des couleurs

38510 ARANDON-PASSINS

France

www.pulsafrance.com

Copyright © 2025 - TechFeeder trademark